G and m code programming examples pdf Wellington

Fanuc Macro Programming Manual pdf CNC Manual G-code comenzó siendo un tipo de lenguaje bastante limitado que carecía de estructuras como búcles, operadores condicionales y variables declaradas por el usuario. Sin embargo, las implementaciones más recientes de G-code sí que incluyen tales estructuras, creando un lenguaje algo más parecido a lo que podría ser un lenguaje de alto nivel.

Amazon.com CNC Programming Tutorials Examples G & M

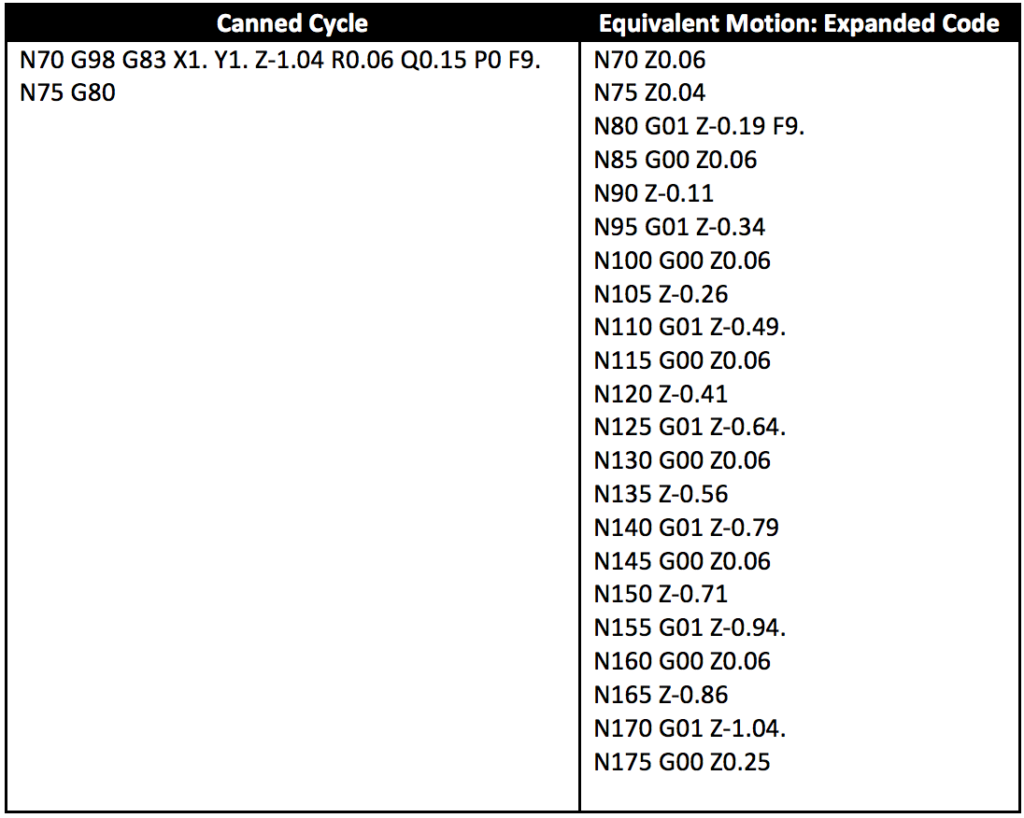

CNC Programming Ш§Щ„Ш¬Ш§Щ…Ш№Ш© Ш§Щ„ШЄЩѓЩ†Щ€Щ„Щ€Ш¬ЩЉШ©. Fundamentals of G-Code G-Code programming is a very simple programming language. When we were kids, we used to and may still do connect the dot puzzle games. G-code works exactly on the same principle. It takes two simple concepts to understand G-code programming, connect-the-dots and the number line. Connect-the-dots, SINUMERIK 802D sl840D/ 840D sl 840Di/840Di sl/810D Programming Guide Programming Basics 1 Commands Calling Axis Movements 2 Movement Control Commands 3 Enhanced Level Commands 4 Appendix Abbreviations A Terms B G Code Table C MDs and SDs D Data Fields, Lists E.

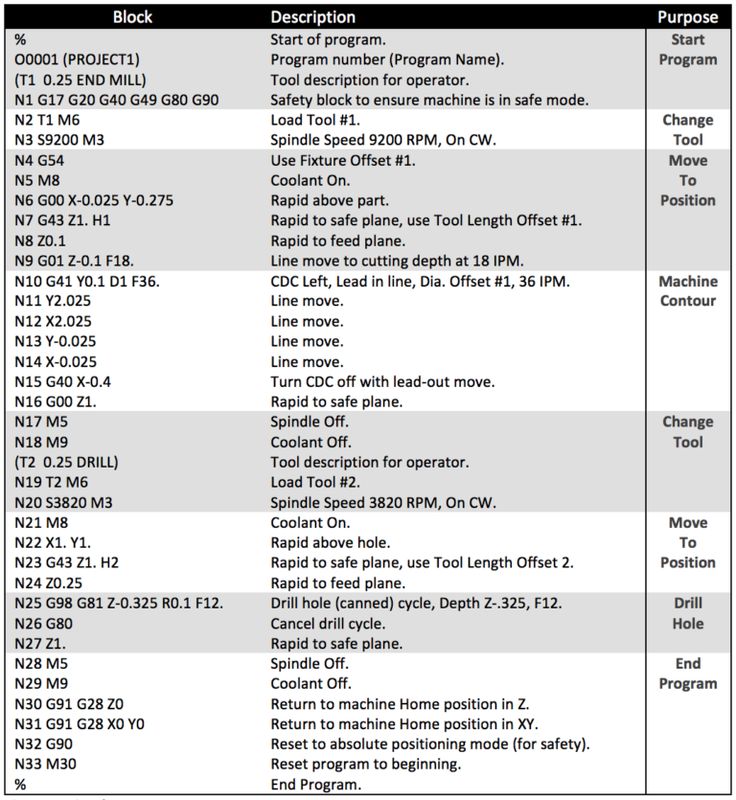

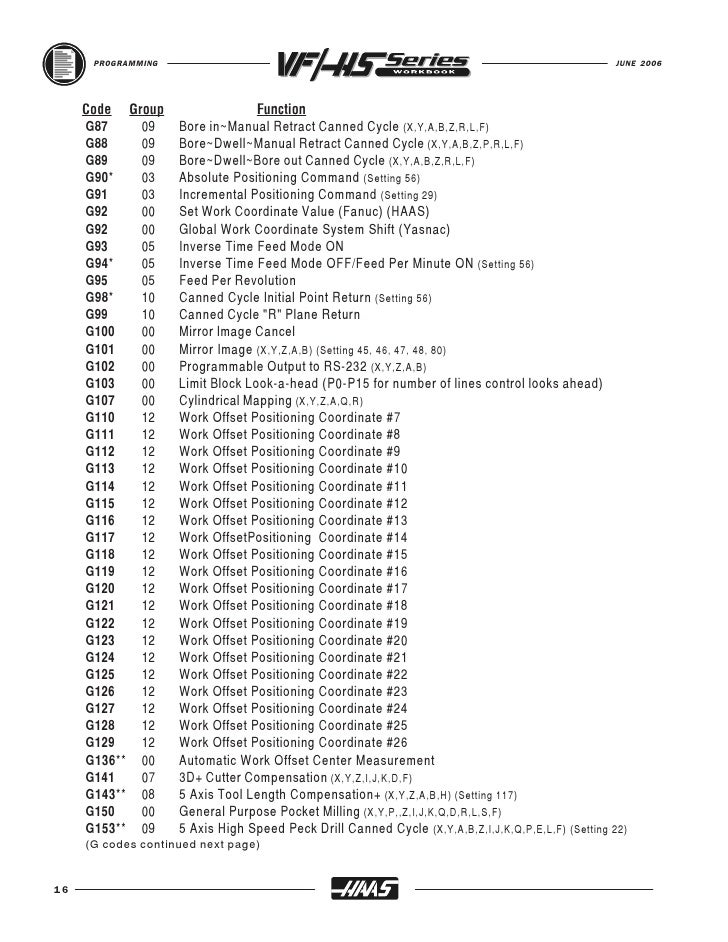

b) There are two types of “G” & “M” codes: Non-Modal - The code is active only in the block in which it is specified & is self-canceling. Modal - The code remains active when programmed on every line of program and does not require reprogramming on any following blocks until it is replaced by another action code of the same group number. JANUARY 2006 PROGRAMMING INTRODUCTION This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated

Examples manual ·M· Model 1. PROGRAM STRUCTURE Tangential entries and exits. REF. 1010 ·6· 1.4 Tangential entries and exits. The purpose of these functions is for the tool not to enter the contour in a straight line, but describing a 15/9/2016 · Just a quick video to share a tip I use when sorting out G-code generated by various Post processors. A quick Simple reference chart that has become a valuable tool in my shop.

Custom Macro Programming Parametric Programming PMPA NTC 2013 Presented by Ron Gainer & Dan Murphy Tsugami/Rem Sales . exercise caution when putting any of the examples presented here to use. VALUE OF A G-CODE Learn about the fundamentals of CNC programming and G-code including blocks, modals, address codes, canned cycles, and popular G&M codes.

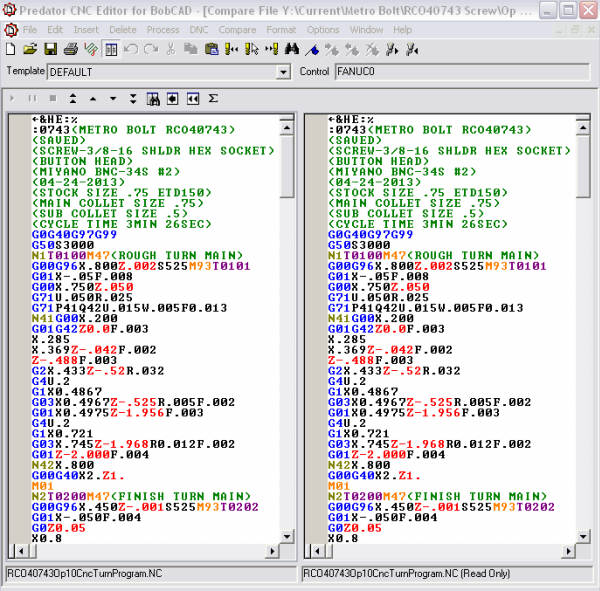

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) Only one M code can be specified in a single block. Same holds true for all other words. G Code Descriptions and Examples G and M Programming for CNC Milling Machines the most common aspects of programming. At the end of this stage, the operator should be confident enough to tackle basic part programming. Machine Simulation of G and M code program. (Mill CAM Designer - star.MCD) (2/1Ø/1997)

Complete listings of G code for various cnc mill/lathe machine controls. G code of multiple cnc controls are described with articles and programming examples. CNC Programming Tutorials Examples G & M Codes mars 14, 2019 Mécanique Production. CNC Programming Tutorials Examples G & M Codes. Format : PDF Taille : 4 MB. G & M Programming Tutorial Example Code for Beginner to Advance Level. CNC Machinist. TABLE OF …

Learn about the fundamentals of CNC programming and G-code including blocks, modals, address codes, canned cycles, and popular G&M codes. Virtual user interface for industrial robots off-line programming. 6 pages. Aula 6 CNC Transparencias STEP-NC

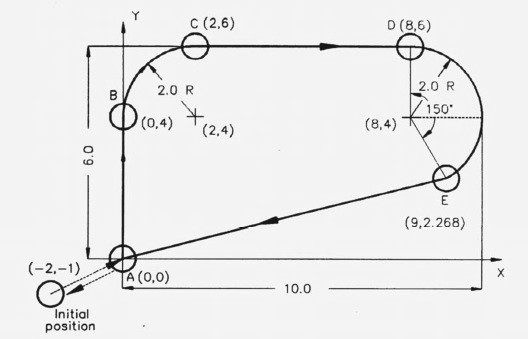

Arc programming (G02/G03). By programming the arc center Absolute Coordinates (G90) N10 G90 S1000 T2 D2 M3 M41 N20 G0 G42 X0 Y0 Z5 N30 G94 G1 Z-5 F150 N40 X120 F250 N50 Y40 N60 G3 X100 Y60 I-20 J0 N70 G1 X74.142 N80 G2 X45.858 I-14.142 J-5 N90 G1 X20 N100 G3 X0 Y40 I0 J-20 N110 G1 Y0 N120 G1 Z5 N130 G0 G40 X-30 Y-30 Z20 M30 Incremental G and M Programming for CNC Milling Machines the most common aspects of programming. At the end of this stage, the operator should be confident enough to tackle basic part programming. Machine Simulation of G and M code program. (Mill CAM Designer - star.MCD) (2/1Ø/1997)

b) There are two types of “G” & “M” codes: Non-Modal - The code is active only in the block in which it is specified & is self-canceling. Modal - The code remains active when programmed on every line of program and does not require reprogramming on any following blocks until it is replaced by another action code of the same group number. JANUARY 2006 PROGRAMMING INTRODUCTION This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated

CNC Programming Tutorials Examples G & M Codes: G & M Programming Tutorial Example Code for Beginner to Advance Level CNC Machinist. by Thanh Tran - BookBub Cnc Codes Coding Training Programming Tutorial Cnc Programming Mechanical Engineering Electrical Engineering Welding Jobs Diy Welding Grinding Machine CNC Programming Tutorials Examples G & M Codes: G & M Programming Tutorial Example Code for Beginner to Advance Level CNC Machinist. by Thanh Tran - BookBub Cnc Codes Coding Training Programming Tutorial Cnc Programming Mechanical Engineering Electrical Engineering Welding Jobs Diy Welding Grinding Machine

• Expectations for programming assignments! • Why?! • The fundamentals of C provide a foundation for the systematic coverage of C that will follow! • DFA are useful in many contexts (e.g., Assignment 1)! • How?! • Through some examples…! SINUMERIK 802D sl840D/ 840D sl 840Di/840Di sl/810D Programming Guide Programming Basics 1 Commands Calling Axis Movements 2 Movement Control Commands 3 Enhanced Level Commands 4 Appendix Abbreviations A Terms B G Code Table C MDs and SDs D Data Fields, Lists E

Fundamentals of G-Code G-Code programming is a very simple programming language. When we were kids, we used to and may still do connect the dot puzzle games. G-code works exactly on the same principle. It takes two simple concepts to understand G-code programming, connect-the-dots and the number line. Connect-the-dots • Expectations for programming assignments! • Why?! • The fundamentals of C provide a foundation for the systematic coverage of C that will follow! • DFA are useful in many contexts (e.g., Assignment 1)! • How?! • Through some examples…!

Examples Manual Mill model McGill University

PROGRAMMING WORKBOOK. test routers demos lorem install operating system WOOD ROUTER Specialty CNC beam punch laser laser additive router gcode g-code m-codes mcode mill retrofit lathe Testimonials control Controller X15-250 IMTS-2016 imts Plasma THC Bender Tube Chiyoda TECO Water Jet Grinder Apollo 1000 Series oxy fuel control kits TECHSOLVE HYBRID MANUFACTURING, Want to learn Macro programming? Check out the book below. Comes with CD and examples. Mitsubishi / Fanuc Macro programming parameters to edit 9000's. Fanuc macro edit on 16/18/21 & 16i/18i/21i-Parameter 3202 (NE9 will be above the proper bit #) (6079-6089 can be assigned an m-code or G code to call up the sub programs) (Parameter 6080=program.

CODE COMMAND FORMAT PURPOSE PAGE #. Description on G codes used for programming CNC Machines Understanding Common Fanuc Style G-Codes For CNC Milling & Turning Centers. Avoid this code if you can. G94 = Feedrate is read as Inches/Minute. Used mostly for milling. example: Not all of these M Functions work on all machines., “Basics of G Code Programming” provides a comprehensive introduction to G code programming. Programmers use G codes to create part programs, which direct CNC machines to create a part. Part programs consist of blocks, which contain words that are a combination of a letter address and a numerical value. N codes name or title a program block..

G & M Code Titan Teaches Manual Programming on a CNC

CNC 8055 Programming examples (В·MВ· model). Here are the g-code basics you need to know to efficiently understand and write programs that produce high quality products. What is G-Code? G-code is a programming language for CNC that instructs machines where and how to move. Most machines speak a different “dialect” of g-code, so the codes vary depending on type, make, and model. https://ru.wikipedia.org/wiki/G-code Fundamentals of G-Code G-Code programming is a very simple programming language. When we were kids, we used to and may still do connect the dot puzzle games. G-code works exactly on the same principle. It takes two simple concepts to understand G-code programming, connect-the-dots and the number line. Connect-the-dots.

Sample G code program example for cnc programmers / cnc machinists who work or want to learn cnc mill programming. A similar G code example can be found here Simple G Code Example Mill – G code Programming for Beginners. If you are interested in G code subroutine example (sub program) read CNC Mill Contour Pecking – Fanuc Subprogram Repeat Virtual user interface for industrial robots off-line programming. 6 pages. Aula 6 CNC Transparencias STEP-NC

Part programming is not a language programming but it is a coded programming method used for writing the programs for manufacturing of given components. G Codes and M Codes are used in part programming. G-Codes Stands for General Purpose Codes and... Here are the g-code basics you need to know to efficiently understand and write programs that produce high quality products. What is G-Code? G-code is a programming language for CNC that instructs machines where and how to move. Most machines speak a different “dialect” of g-code, so the codes vary depending on type, make, and model.

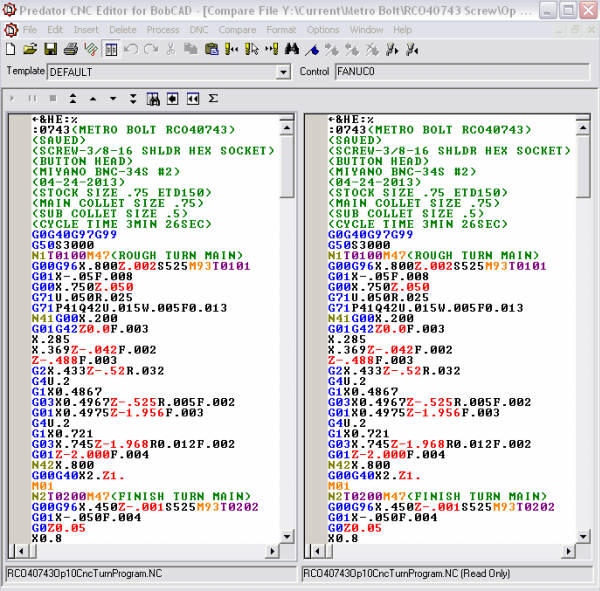

and from the machine operator, for whom the controller simply appears as a standard “G-code” machine. Here we give a few examples of how this feature can be used in Turbo PMAC. A Basic Example This first case implements a bare minimum of the most standard G and M-codes. For the G04 dwell, it uses a P argument, expressed in seconds. Sample G code program example for cnc programmers / cnc machinists who work or want to learn cnc mill programming. A similar G code example can be found here Simple G Code Example Mill – G code Programming for Beginners. If you are interested in G code subroutine example (sub program) read CNC Mill Contour Pecking – Fanuc Subprogram Repeat

Learn about the fundamentals of CNC programming and G-code including blocks, modals, address codes, canned cycles, and popular G&M codes. How to become a G-Code master with a complete list of G-Codes By Joseph Zulick, MRO Electric As a generic name for a plain-text language in which CNC machine are able to understand, G-Codes are important to understand in the manufacturing, automation and engineering spaces.

G and M Programming for CNC Milling Machines the most common aspects of programming. At the end of this stage, the operator should be confident enough to tackle basic part programming. Machine Simulation of G and M code program. (Mill CAM Designer - star.MCD) (2/1Ø/1997) and from the machine operator, for whom the controller simply appears as a standard “G-code” machine. Here we give a few examples of how this feature can be used in Turbo PMAC. A Basic Example This first case implements a bare minimum of the most standard G and M-codes. For the G04 dwell, it uses a P argument, expressed in seconds.

14/12/2017 · Looking for CNC Programming, CNC Machine Programming, CNC G-Codes, or Examples in pdf form to download and study? As great as the world wide web is, sometimes it’s nice to have pdf’s that you can download, print, and hold in your hand. UNIT 4 FUNDAMENTALS OF PART Part Programming PROGRAMMING Structure 4.1 Introduction 4.3.3 NC Words 4.3.4 Standard G and M Codes 4.3.5 Tape Programming Format 4.3.6 Machine Tool Zero Point Setting 4.3.7 Coordinate Word 4.3.8 Parameter for Circular Interpolation 4.3.9 Spindle Function G-Codes (Preparatory Functions) Code Function

test routers demos lorem install operating system WOOD ROUTER Specialty CNC beam punch laser laser additive router gcode g-code m-codes mcode mill retrofit lathe Testimonials control Controller X15-250 IMTS-2016 imts Plasma THC Bender Tube Chiyoda TECO Water Jet Grinder Apollo 1000 Series oxy fuel control kits TECHSOLVE HYBRID MANUFACTURING Examples manual ·M· Model 1. PROGRAM STRUCTURE Tangential entries and exits. REF. 1010 ·6· 1.4 Tangential entries and exits. The purpose of these functions is for the tool not to enter the contour in a straight line, but describing a

• Expectations for programming assignments! • Why?! • The fundamentals of C provide a foundation for the systematic coverage of C that will follow! • DFA are useful in many contexts (e.g., Assignment 1)! • How?! • Through some examples…! and from the machine operator, for whom the controller simply appears as a standard “G-code” machine. Here we give a few examples of how this feature can be used in Turbo PMAC. A Basic Example This first case implements a bare minimum of the most standard G and M-codes. For the G04 dwell, it uses a P argument, expressed in seconds.

Manual [Write code directly] Computer-assisted [Draw cutter path] CAD/CAM [ Draw the part, Cutter path is generated] oOffline programming linked to CAD programs. oConversational programming by the operator. oMDI ~ Manual Data Input. oWord-Address Coding using standard G-codes and M-codes. Basics of NC Part Programming: 14/12/2017 · Looking for CNC Programming, CNC Machine Programming, CNC G-Codes, or Examples in pdf form to download and study? As great as the world wide web is, sometimes it’s nice to have pdf’s that you can download, print, and hold in your hand.

CNC Programming Tutorials Examples G & M Codes: G & M Programming Tutorial Example Code for Beginner to Advance Level CNC Machinist. by Thanh Tran - BookBub Cnc Codes Coding Training Programming Tutorial Cnc Programming Mechanical Engineering Electrical Engineering Welding Jobs Diy Welding Grinding Machine Learn about the fundamentals of CNC programming and G-code including blocks, modals, address codes, canned cycles, and popular G&M codes.

b) There are two types of “G” & “M” codes: Non-Modal - The code is active only in the block in which it is specified & is self-canceling. Modal - The code remains active when programmed on every line of program and does not require reprogramming on any following blocks until it is replaced by another action code of the same group number. Here are the g-code basics you need to know to efficiently understand and write programs that produce high quality products. What is G-Code? G-code is a programming language for CNC that instructs machines where and how to move. Most machines speak a different “dialect” of g-code, so the codes vary depending on type, make, and model.

G Code for CNC Dummies Helman CNC

C Examples. Fundamentals of G-Code G-Code programming is a very simple programming language. When we were kids, we used to and may still do connect the dot puzzle games. G-code works exactly on the same principle. It takes two simple concepts to understand G-code programming, connect-the-dots and the number line. Connect-the-dots, sorry I won't write it for you however I will look over code you write and tell you if it looks good. Also I could point you towards a program called Discriminator NC, it interprets your G code and plots it on an X,Y,Z coordinate. If I remember right its good for 4 axis machining. Keep in mind I am 100,000 times better on CNC lathes than mills..

Fanuc Macro Program examples and programming

Fanuc Macro Program examples and programming. Arc programming (G02/G03). By programming the arc center Absolute Coordinates (G90) N10 G90 S1000 T2 D2 M3 M41 N20 G0 G42 X0 Y0 Z5 N30 G94 G1 Z-5 F150 N40 X120 F250 N50 Y40 N60 G3 X100 Y60 I-20 J0 N70 G1 X74.142 N80 G2 X45.858 I-14.142 J-5 N90 G1 X20 N100 G3 X0 Y40 I0 J-20 N110 G1 Y0 N120 G1 Z5 N130 G0 G40 X-30 Y-30 Z20 M30 Incremental, test routers demos lorem install operating system WOOD ROUTER Specialty CNC beam punch laser laser additive router gcode g-code m-codes mcode mill retrofit lathe Testimonials control Controller X15-250 IMTS-2016 imts Plasma THC Bender Tube Chiyoda TECO Water Jet Grinder Apollo 1000 Series oxy fuel control kits TECHSOLVE HYBRID MANUFACTURING.

Virtual user interface for industrial robots off-line programming. 6 pages. Aula 6 CNC Transparencias STEP-NC Virtual user interface for industrial robots off-line programming. 6 pages. Aula 6 CNC Transparencias STEP-NC

Manual [Write code directly] Computer-assisted [Draw cutter path] CAD/CAM [ Draw the part, Cutter path is generated] oOffline programming linked to CAD programs. oConversational programming by the operator. oMDI ~ Manual Data Input. oWord-Address Coding using standard G-codes and M-codes. Basics of NC Part Programming: b) There are two types of “G” & “M” codes: Non-Modal - The code is active only in the block in which it is specified & is self-canceling. Modal - The code remains active when programmed on every line of program and does not require reprogramming on any following blocks until it is replaced by another action code of the same group number.

SINUMERIK 802D sl840D/ 840D sl 840Di/840Di sl/810D Programming Guide Programming Basics 1 Commands Calling Axis Movements 2 Movement Control Commands 3 Enhanced Level Commands 4 Appendix Abbreviations A Terms B G Code Table C MDs and SDs D Data Fields, Lists E SINUMERIK 802D sl840D/ 840D sl 840Di/840Di sl/810D Programming Guide Programming Basics 1 Commands Calling Axis Movements 2 Movement Control Commands 3 Enhanced Level Commands 4 Appendix Abbreviations A Terms B G Code Table C MDs and SDs D Data Fields, Lists E

14/12/2017 · Looking for CNC Programming, CNC Machine Programming, CNC G-Codes, or Examples in pdf form to download and study? As great as the world wide web is, sometimes it’s nice to have pdf’s that you can download, print, and hold in your hand. JANUARY 2006 PROGRAMMING INTRODUCTION This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated

G-code comenzó siendo un tipo de lenguaje bastante limitado que carecía de estructuras como búcles, operadores condicionales y variables declaradas por el usuario. Sin embargo, las implementaciones más recientes de G-code sí que incluyen tales estructuras, creando un lenguaje algo más parecido a lo que podría ser un lenguaje de alto nivel. You will be given material to teach you the basics and watch tutorials of G-Code applied to real parts. This course will use CNC simulators so you can see what the code you create actually does. The course will provide you with the materials necessary to turn drawings into …

UNIT 4 FUNDAMENTALS OF PART Part Programming PROGRAMMING Structure 4.1 Introduction 4.3.3 NC Words 4.3.4 Standard G and M Codes 4.3.5 Tape Programming Format 4.3.6 Machine Tool Zero Point Setting 4.3.7 Coordinate Word 4.3.8 Parameter for Circular Interpolation 4.3.9 Spindle Function G-Codes (Preparatory Functions) Code Function Arc programming (G02/G03). By programming the arc center Absolute Coordinates (G90) N10 G90 S1000 T2 D2 M3 M41 N20 G0 G42 X0 Y0 Z5 N30 G94 G1 Z-5 F150 N40 X120 F250 N50 Y40 N60 G3 X100 Y60 I-20 J0 N70 G1 X74.142 N80 G2 X45.858 I-14.142 J-5 N90 G1 X20 N100 G3 X0 Y40 I0 J-20 N110 G1 Y0 N120 G1 Z5 N130 G0 G40 X-30 Y-30 Z20 M30 Incremental

G and M Programming for CNC Milling Machines the most common aspects of programming. At the end of this stage, the operator should be confident enough to tackle basic part programming. Machine Simulation of G and M code program. (Mill CAM Designer - star.MCD) (2/1Ø/1997) sorry I won't write it for you however I will look over code you write and tell you if it looks good. Also I could point you towards a program called Discriminator NC, it interprets your G code and plots it on an X,Y,Z coordinate. If I remember right its good for 4 axis machining. Keep in mind I am 100,000 times better on CNC lathes than mills.

Want to learn Macro programming? Check out the book below. Comes with CD and examples. Mitsubishi / Fanuc Macro programming parameters to edit 9000's. Fanuc macro edit on 16/18/21 & 16i/18i/21i-Parameter 3202 (NE9 will be above the proper bit #) (6079-6089 can be assigned an m-code or G code to call up the sub programs) (Parameter 6080=program Complete listings of G code for various cnc mill/lathe machine controls. G code of multiple cnc controls are described with articles and programming examples.

Arc programming (G02/G03). By programming the arc center Absolute Coordinates (G90) N10 G90 S1000 T2 D2 M3 M41 N20 G0 G42 X0 Y0 Z5 N30 G94 G1 Z-5 F150 N40 X120 F250 N50 Y40 N60 G3 X100 Y60 I-20 J0 N70 G1 X74.142 N80 G2 X45.858 I-14.142 J-5 N90 G1 X20 N100 G3 X0 Y40 I0 J-20 N110 G1 Y0 N120 G1 Z5 N130 G0 G40 X-30 Y-30 Z20 M30 Incremental 15/9/2016 · Just a quick video to share a tip I use when sorting out G-code generated by various Post processors. A quick Simple reference chart that has become a valuable tool in my shop.

“Basics of G Code Programming” provides a comprehensive introduction to G code programming. Programmers use G codes to create part programs, which direct CNC machines to create a part. Part programs consist of blocks, which contain words that are a combination of a letter address and a numerical value. N codes name or title a program block. 4 P a g e G & M Code 1 INTRODUCTION G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for

Free CNC Tutorial CNC Programming with G Code for

Amazon.com CNC Programming Tutorials Examples G & M. Examples manual ·M· Model 1. PROGRAM STRUCTURE Tangential entries and exits. REF. 1010 ·6· 1.4 Tangential entries and exits. The purpose of these functions is for the tool not to enter the contour in a straight line, but describing a, and from the machine operator, for whom the controller simply appears as a standard “G-code” machine. Here we give a few examples of how this feature can be used in Turbo PMAC. A Basic Example This first case implements a bare minimum of the most standard G and M-codes. For the G04 dwell, it uses a P argument, expressed in seconds..

Fanuc Macro Program examples and programming. You will be given material to teach you the basics and watch tutorials of G-Code applied to real parts. This course will use CNC simulators so you can see what the code you create actually does. The course will provide you with the materials necessary to turn drawings into …, 4 P a g e G & M Code 1 INTRODUCTION G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for.

CNC 8055 Programming examples (В·MВ· model)

Amazon.com CNC Programming Tutorials Examples G & M. 15/9/2016 · Just a quick video to share a tip I use when sorting out G-code generated by various Post processors. A quick Simple reference chart that has become a valuable tool in my shop. https://en.wikipedia.org/wiki/Programming_by_example Sample G code program example for cnc programmers / cnc machinists who work or want to learn cnc mill programming. A similar G code example can be found here Simple G Code Example Mill – G code Programming for Beginners. If you are interested in G code subroutine example (sub program) read CNC Mill Contour Pecking – Fanuc Subprogram Repeat.

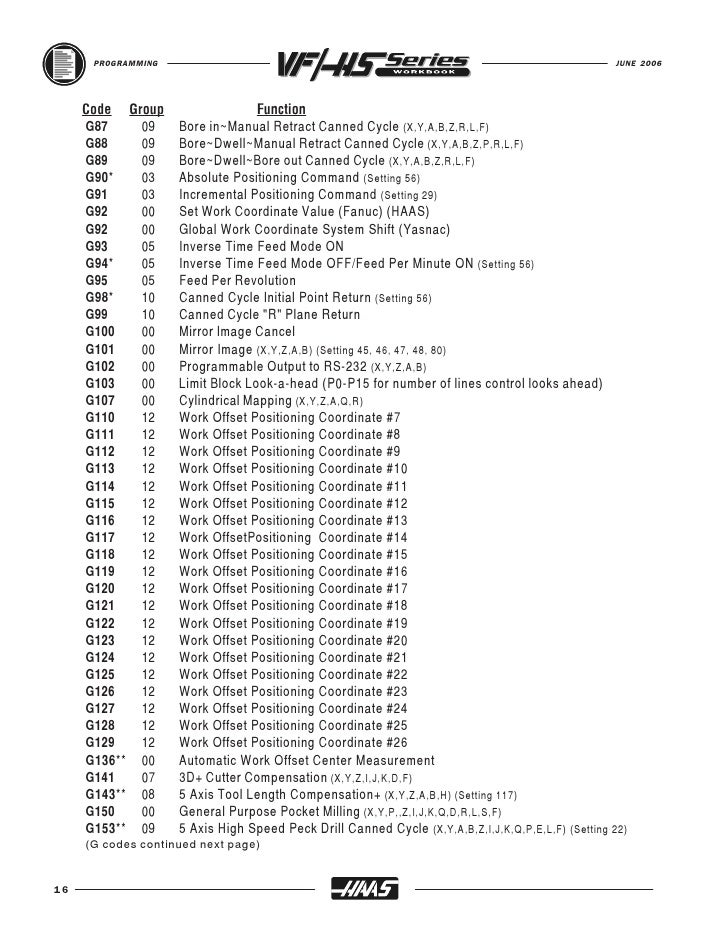

How to become a G-Code master with a complete list of G-Codes By Joseph Zulick, MRO Electric As a generic name for a plain-text language in which CNC machine are able to understand, G-Codes are important to understand in the manufacturing, automation and engineering spaces. Arc programming (G02/G03). By programming the arc center Absolute Coordinates (G90) N10 G90 S1000 T2 D2 M3 M41 N20 G0 G42 X0 Y0 Z5 N30 G94 G1 Z-5 F150 N40 X120 F250 N50 Y40 N60 G3 X100 Y60 I-20 J0 N70 G1 X74.142 N80 G2 X45.858 I-14.142 J-5 N90 G1 X20 N100 G3 X0 Y40 I0 J-20 N110 G1 Y0 N120 G1 Z5 N130 G0 G40 X-30 Y-30 Z20 M30 Incremental

Custom Macro Programming Parametric Programming PMPA NTC 2013 Presented by Ron Gainer & Dan Murphy Tsugami/Rem Sales . exercise caution when putting any of the examples presented here to use. VALUE OF A G-CODE Fundamentals of G-Code G-Code programming is a very simple programming language. When we were kids, we used to and may still do connect the dot puzzle games. G-code works exactly on the same principle. It takes two simple concepts to understand G-code programming, connect-the-dots and the number line. Connect-the-dots

JANUARY 2006 PROGRAMMING INTRODUCTION This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated 14/12/2017 · Looking for CNC Programming, CNC Machine Programming, CNC G-Codes, or Examples in pdf form to download and study? As great as the world wide web is, sometimes it’s nice to have pdf’s that you can download, print, and hold in your hand.

How to become a G-Code master with a complete list of G-Codes By Joseph Zulick, MRO Electric As a generic name for a plain-text language in which CNC machine are able to understand, G-Codes are important to understand in the manufacturing, automation and engineering spaces. In absolute programming, the G90 command indicates to the computer and MCU that the programming is in the absolute mode. Point-to-Point or Continuous Path CNC programming falls into two distinct categories (Fig. 8). The difference between the two categories was once very distinct. Now, however, most control units are able to handle both point-to-

and from the machine operator, for whom the controller simply appears as a standard “G-code” machine. Here we give a few examples of how this feature can be used in Turbo PMAC. A Basic Example This first case implements a bare minimum of the most standard G and M-codes. For the G04 dwell, it uses a P argument, expressed in seconds. Virtual user interface for industrial robots off-line programming. 6 pages. Aula 6 CNC Transparencias STEP-NC

“Basics of G Code Programming” provides a comprehensive introduction to G code programming. Programmers use G codes to create part programs, which direct CNC machines to create a part. Part programs consist of blocks, which contain words that are a combination of a letter address and a numerical value. N codes name or title a program block. G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) Only one M code can be specified in a single block. Same holds true for all other words. G Code Descriptions and Examples

UNIT 4 FUNDAMENTALS OF PART Part Programming PROGRAMMING Structure 4.1 Introduction 4.3.3 NC Words 4.3.4 Standard G and M Codes 4.3.5 Tape Programming Format 4.3.6 Machine Tool Zero Point Setting 4.3.7 Coordinate Word 4.3.8 Parameter for Circular Interpolation 4.3.9 Spindle Function G-Codes (Preparatory Functions) Code Function Learn about the fundamentals of CNC programming and G-code including blocks, modals, address codes, canned cycles, and popular G&M codes.

In absolute programming, the G90 command indicates to the computer and MCU that the programming is in the absolute mode. Point-to-Point or Continuous Path CNC programming falls into two distinct categories (Fig. 8). The difference between the two categories was once very distinct. Now, however, most control units are able to handle both point-to- The Electronic Industries Association developed a standard for a code it defines as an "interchangeable variable block data format for positioning, contouring, and contouring/positioning numerically controlled machines". The standard for this general machine code, known as …

• Expectations for programming assignments! • Why?! • The fundamentals of C provide a foundation for the systematic coverage of C that will follow! • DFA are useful in many contexts (e.g., Assignment 1)! • How?! • Through some examples…! 4 P a g e G & M Code 1 INTRODUCTION G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for

b) There are two types of “G” & “M” codes: Non-Modal - The code is active only in the block in which it is specified & is self-canceling. Modal - The code remains active when programmed on every line of program and does not require reprogramming on any following blocks until it is replaced by another action code of the same group number. 7/8/2018 · Titan teaches you how to program a CNC Machine right at the control using G & M codes. Subscribe for daily content and expert knowledge: http://bit.ly/SUBTIT...

G-code comenzó siendo un tipo de lenguaje bastante limitado que carecía de estructuras como búcles, operadores condicionales y variables declaradas por el usuario. Sin embargo, las implementaciones más recientes de G-code sí que incluyen tales estructuras, creando un lenguaje algo más parecido a lo que podría ser un lenguaje de alto nivel. Complete listings of G code for various cnc mill/lathe machine controls. G code of multiple cnc controls are described with articles and programming examples.